热门关键词: Muffle Furnace 高温马弗炉 硅片扩散炉 硅片快速退火炉 稀土金属蒸馏提纯高温炉 稀土金属蒸馏提纯高温真空炉 钛在真空环境中的使用温度范围

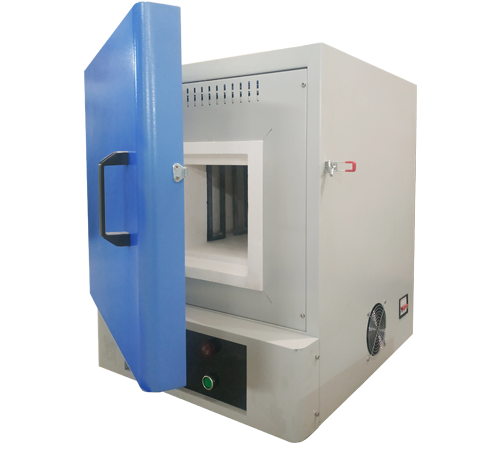

1400℃ Muffle Furnace 1400度高温马弗炉

高温马弗炉是一种实验室用高温实验设备,能够达到1400度以上。这种高温马弗炉可用于实验室中进行高温烧制、热处理、试样分析等研究工作。高温马弗炉由高温腔体、加热元件、温度控制系统、炉体外壳等部分构成。加热元件采用硅碳棒加热,加热温度可达1400度。

Furnace Name:1400℃ Muffle Furnace

炉名:1400℃马弗炉

Model NO.:STR18-14

型号:STR18-14

Furnace Structure:BOX

炉膛结构:BOX

Furnace Type:Lab Muffle Furnace

炉型:实验室马夫炉

Chamber Size:W250xd300xh250mm

腔室尺寸:W250xd300xh250mm

Specification:18 liters

规格:18升

Max Temperature:1400℃

设计温度:1400℃

Working Temperature:1300℃

工作温度:1300摄氏度

Heating Element:Sic Rod

加热元件:Sic棒

Thermocouple:Type S

热电偶:S型

Chamber Material:Ceramic Fiber Board

腔体材料:陶瓷纤维板

Temperature Control: Pid

温度控制:Pid

Power Supply:AC380/7kw/50Hz

电源:AC380/7kw/50Hz

Transport Package:Wooden Case

运输包装:出口木箱

Packing Size:W700*D970*H1000mm

包装尺寸:W700*D970*H1000mm

Factory:SIGMA

工厂:SIGMA

Origin:China

原产地:中国

| Model | STR-M3-14 | STR-M8-14 | STR-M18-14 | STR-M36-14 |

| Chamber Size (W*D*H) mm | 150x150x150 | 200x200x200 | 250x300x250 | 300x400x300 |

| Power supply | 220V/2.5KW | 220V/4KW | 380V/7KW | 380V-12KW |

| Type | Front-loading | |||

| Usage | The product is suitable for elemental analysis, measurement and steel hardening, annealing, tempering, heat treatment and heating in laboratory, industrial and mining enterprises, scientific research units,can also be used for sintering of metal, stone, ceramic, dissolution analysis of high-temperature heating. | |||

| Furnace structure |

1. The furnace is consist of heating system and temperature controller system 2. chamber is consist of insulation material and heating elements 3. Temperature controller is consist of PID controller, control elements and thermocouple 4. The furnace body and temperature controller are designed independently |

|||

| Max temperature | 1400ºC | |||

| Working temperature | 1300ºC | |||

| Heating Rate | ≤15ºC/min (suggest 10ºC/min for longer life using of furnace) | |||

| Heating Element | Powerful silicon carbide heating elements ensure quick heating and a uniform chamber temperature | |||

| Chamber material |

1. Furnace Lining: Furnace material is 1400ºC high-purity Light Mullite bricks 2. Thermal Insulation Material: The furnace is insulated by polycrystalline alumina ceramic fibers with temperature resistance of 1500ºC |

|||

| Temp. Uniformity | ±10°C | |||

| Thermocouple |

S type Feature one testing point, testing from its back wall |

|||

| Temperature Controller |

1. Control system integrated in the furnace base, Defined application within the constraints of the operating instructions 2. Furnace temperature controller utilizes Intelligent PID 4 group 8 segments program 3. Feature single setpoint digital control, LED display of actual temperature VS set point 4. A high-precision digital microprocessor controller fitted with self-tuning and manual PID settings makes temperature and other parameters easy to control 5. Temperature controller Precision ±1ºC |

|||

| Electronic component | Delixi maker air switch, buttons, solid-state relay, A.C contactor etc. | |||

| Furnace Shell |

1. High quality cold-rolled steel sheets CNC processing 2. Environmental electrostatic plastic-spraying on surface after deoiling, derusting, phosphating etc. nine processes 3. Energy efficient insulation keeps exterior safe to touch |

|||

| Safety Precautions |

1. Overheating & Broken thermocouple protection 2. Leakage circuit breaker 3. Automatic power off when furnace door opens (optional function) 4. Over-temperature protection and alarm allow for operation without attendant(s) 5. Microprocessor-based PID control with self-tuning capability to prevent overshooting of set temperature |

|||

| Supply Scope |

1. One furnace body 2. One set of temperature controller system 3. Three-meter power line 4. One thermocouple 5. One pair of crucible stongs 6. One pair of high temperature furnace gloves 7. An instruction book |

|||

| Optional Accessories |

1. Alunina boats 2. paperless recorder 3. exhaust chimney |

|||

| Certification | ISO9001 CE | |||

| Warranty |

1. One year of equipment quality guarantee (excluding vulnerable parts: resistance wire, thermocouple, etc.). 2. Damage caused by major manufacturing defects during the warranty period shall be repaired free of charge by the manufacturer 3. The user shall bear the maintenance cost for the damage caused by the user's improper manual operation during the warranty period. 4. Damage occurring after the warranty period, the manufacturer charges the cost of spare parts and labor for paid maintenance. |

|||

Standard package list

| Item Description | Qutity | Image |

| muffle furnace | 1 set | |

| Type S thermocouple | 1 pc | |

| Alunina Cusion block | 1 pc | |

| Stainless steel tongs | 1 pair | |

| 3-meter power line | 1 set | |

| Thermal gloves | 1 pair | |

| Furnace operation manual & temperature controller manual | 1 pc |

Standard Packing for lab muffle furnace:

1.The muffle furnace was warped with enrivonmental plastic stretch film, then fixed well on the fumigation-free pallet

2.Tailored polywood case, coupled perfectly with the pallet

3.Filled with polyfoam, fit well between the furnace body and the case in all sides

4.Easy-to-identify double-sided outer box print logos and shippment marks

Delivery Time: 30 working days against receiving advanced payment

Port: Shanghai/Qingdao

Company Information

Luoyang Sigma Furnace Technology Co., Ltd. is a high-tech enterprise located in Luoyang area of Henan, China Free Trade Zone. Sigma is one of the leading electric heat furnace manufacturers in China. The company designs, manufacturers and sells kinds of electric resistance furnaces and provides the professional solutions for customers in lab and heat industry. Sigma has delivered its furnaces to more than 78 countries and the team is fully dedicated to working for their beloved career.

Sigma products cover 1000ºC~1800ºC Muffle furnace, Tube furnace, Vacuum furnace, Dental furnace, Industrial furnace, elevator furnace, car bottom furnace, degreasing furnace, heardening furnace, annealing furnace, pusher furnace, shutterpottery kiln and so on

Our goal is to continuously meet the various demands for various kinds of high temperature heating treatment industrial muffle furnace and to be the world first-class enterprise with providing excellent service and high-quality products for our cooperation partners!

1200度快速升温管式炉..

详细了解

2200度高纯度石英会与钨反应吗..

详细了解

稀土金属蒸馏提纯高温炉..

详细了解

50Kg稀土金属蒸馏提纯设备(2300℃)稀土金属蒸馏提纯高温真空炉式用于制备高纯稀土金属的关键设备。..

详细了解

钛在真空环境中的使用温度范围..

详细了解